The MG45 is a high pressure homogeniser that supports pressures up to 600 bar and capacities up to 25000 liters per hour.

The MG45 is a high pressure homogeniser that supports pressures up to 600 bar and capacities up to 25000 liters per hour.

-

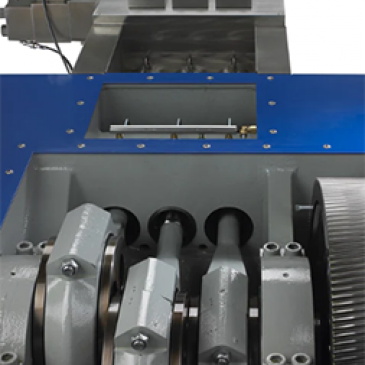

3 plungers

-

High-pressure pump or homogeniser

-

Aseptic available

-

Pump valves: Ball or Spherical

Weight MG45: 5000 kg

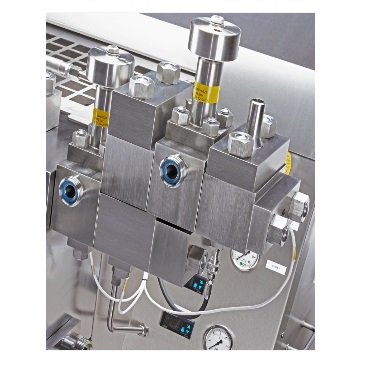

Cylinder block:

- Forged “one-piece” cylinder block made 1.4418 high tensile stainless steel. The design meets the highest sanitary standards and is suitable for C.I.P. cleaning.

- Protection cover enclosing the cylinder block, at ergonomic height for easy inspection access.

- Spherical type pump valves, with field replaceable tapered pump valve seats, made of special wear resistant Rexalloy®, suitable for moderately viscous and moderately abrasive products.

- Plunger packing V-shape, spring loaded, FDA approved/ Food safe materials

- Plunger cooling, integrated in the cylinder block, with flow restrictor.

- Hardened stainless steel 17-4ph – 3 pieces

- Analogue pressure gauge, with sanitary membrane, for Total operating pressure.

Homogenising Valve:

- Two-stage homogenising valve assembly, wear resistant Rexalloy® valve parts and impact ring.

- Hydraulic actuated homogenising valve assembly

- Manual control on the machine, with local manual control valves.

Base and sub-base:

- Cast iron machine base with integrated 1:5 gear reduction

- Pressure lubrication of all bearings and cross heads with an electrical lubrication oil pump.

- Air cooled lubrication oil cooling system, with heat exchanger.

- Analogue pressure gauge for lubrication oil pressure.

- Stainless steel sub-base frame with height adjustable feet 10 – 18 cm ground clearance.

- Stainless steel machine cladding with removable panels for easy access.

Glyanec

Glyanec