Cooling and heating of dairy, brewery, beverage and viscous products and pasteurization in some applications.

1) Adjustable feet ± 30 mm on BASE-3, BASE-6 and BASE-10.

2) Adjustable feet ± 50 mm on BASE-11

The number of tightening bolts vary for different types. Recommended free space around the unit is 1.0 meter at sides and frame head end.

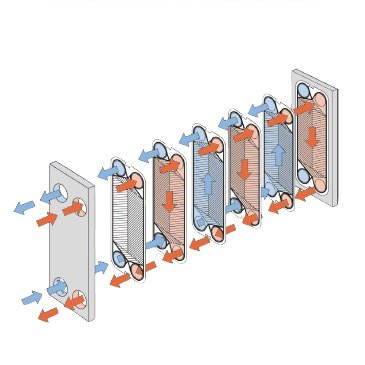

Working principle

The plate heat exchanger consists of a pack of corrugated metal plates with portholes for the passage of two fluids between which heat transfer will take place. The plate pack is assembled between a frame plate and a pressure plate and compressed by tightening bolts. The plates are fitted with a gasket which seals the channel and directs the fluids into alternate channels. The number of plates are determined by the flow rate, physical properties of the fluids, pressure drop and temperature program. The plate corrugations promote fluid turbulence and support the plates against differential pressure.

Gaskets: The plates are supplied with glue-free Clip-On gaskets, which are easy to replace even with the plates still standing in the frame.

Plate Types: M3, M3G, M6, M6M, M6MG, M10B, M10M, TL10B and TL10P

Standard Materials:

Plates Stainless steel AISI 304, AISI 316 or titanium

Gaskets: Nitrile-FDA, EPDM or EPDM-FDA.

Clip-On design: Frame Frame and pressure plate in solid stainless steel for Base 3, 6 and 10. Outer surfaces in various grades of stainless steel. Movable nuts on tightening bolts in chromium plated brass

Technical Data

Mechanical design pressure (g) / Temperature: 10 bar/160°C

According to European pressure vessel directive (PED).

Complies with Alfa Laval Sound Engineering Standard (ALS).

Glyanec

Glyanec